Get the best out of your forklift's li-ion battery

This article has been supplied.

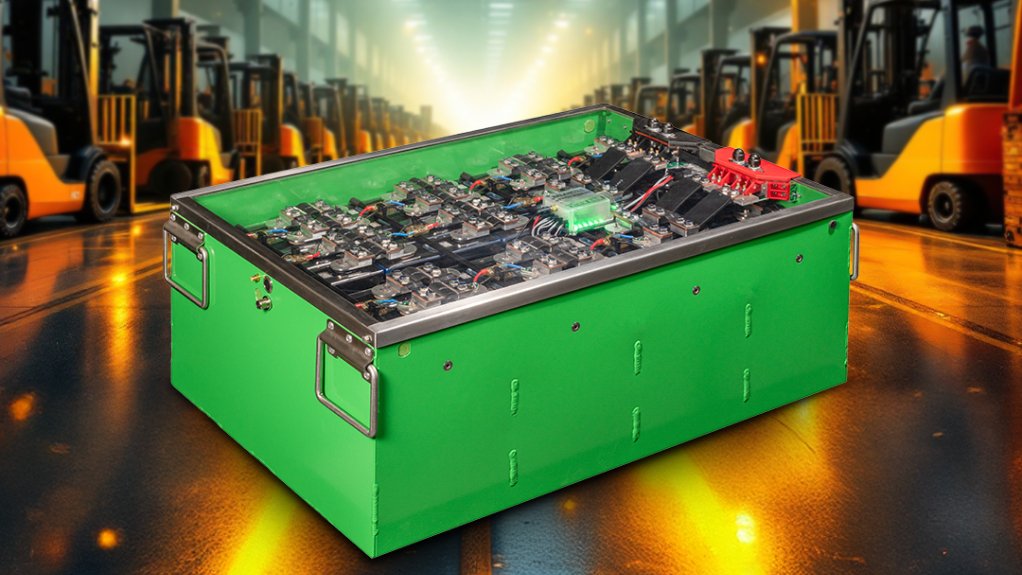

With most forklifts now powered by lithium-ion batteries – due to their superior efficiency, longer lifespan and faster charging times compared to traditional lead-acid batteries – users can maximise their potential by following best practices for maintenance and use.

Duan Tredoux, National Operations Manager for Industrial Power, a division of CFAO Equipment, says there are several effective ways for operations such as distribution centres, warehouses and manufacturing facilities to maximise the performance of their lithium-ion batteries and ensure optimum power in motion.

“While lithium-ion batteries do not require the same maintenance regime as lead-acid batteries, they can last longer and perform better if they are properly charged and cared for.”

Avoid extreme overcharging or discharging

Lithium-ion batteries don’t need to be fully discharged before being recharged, unlike their lead-acid counterparts. This is because they are not subject to the same memory effect as older battery technologies are. In fact, partial charging is better for the battery’s lifespan and operators should aim to keep the battery charge level between 10% and 100% to maintain battery longevity.

Tredoux notes that lithium-ion batteries don’t require frequent full discharges to maintain performance. “Allowing a battery to reach 0% can lead to voided warranties as well as a reduction in life capacity over time. Not only is charging during breaks or between shifts an efficient way to ensure forklifts are always ready to operate, but it also places less strain on the battery.”

Invest in proper charging infrastructure

Charging stations – or dedicated forklift parking spaces – should be equipped with chargers designed for the forklift battery being used. Chargers that are not compatible with the battery model or are of poor quality can lead to sub-optimal charging. This can, in turn, reduce the operations efficiency as batteries then need to be on charge for longer periods.

Tredoux says Industrial Power introduced Eco-chargers in late-2024. “These chargers offer 97% energy efficiency compared to the 90% average offered by standard industry chargers. Operations should also consider investing in lithium-ion forklift batteries that have advanced battery management systems (BMS) to ensure safe and efficient charging,” he adds.

Steer clear of extreme temperatures

High temperatures can accelerate chemical reactions inside lithium-ion batteries, which can lead to faster degradation. Alternatively, very low temperatures can reduce battery capacity and overall efficiency too. In environments that have fluctuating temperatures, forklifts should be stored in temperature-controlled areas when not in use.

Conduct regular checks

Even though lithium-ion batteries require significantly less maintenance than lead-acid batteries, it is important to conduct health checks annually or biannually (in tough applications). Charging systems and batteries should be inspected for signs of wear, corrosion or damage dependant on the operation as well as conditions

Tredoux urges users to keep their chargers clean. “Blocked or dirty chargers result in inefficient charging which, in turn, can lead to battery drainage due to not being able to charge quickly enough.”

Battery management systems should also be checked by the customer to ensure they are working correctly as they monitor the health of the battery and can alert operators to any potential issues, helping to extend battery life and prevent unexpected failures.

Battery monitoring systems a must

Most lithium-ion batteries come with monitoring systems that provide real-time data on charge levels, temperature, voltage and overall health. Gaining an understanding of each battery’s performance over time can help optimise a fleet’s operation and prevent batteries from going into an unsafe state.

This information can be used to schedule charging cycles, identify underperforming batteries and predict when a battery may need replacement, ultimately preventing downtime.

Ensure battery longevity and efficiency

By following these best practices, operations can maximise the longevity and efficiency of forklift fleets, reduce costs related to battery replacements and ensure facilities operate smoothly and without disruption. “With the right care and attention, lithium-ion batteries can power operations for many years,” concludes Tredoux.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation